Solely dedicated to the supply and support of Formlabs’ range of 3D printers, Advent 3D’s background in engineering and design provides a deep understanding of the requirements of these industries and is uniquely positioned to help customers use Formlabs’ 3D printing technologies to reduce costs, improve efficiency and reduce times to market.

Here is an introduction to both the SLA and SLS printers from Formlabs:

Form 3+

Introduced in January 2022, the Form 3+ produces functional, high-quality prototypes and end-use parts in record time. An affordable, industrial-quality 3D printer that reliably delivers, the Form 3+ quickly goes from design to finished part thanks to its streamlined, end-to-end workflow. The powerful, high-intensity laser and precisely tuned settings for every material enable fast printing, and the automated washing and post-curing system is designed to get the most out of your printed parts. The Form 3+ refines Formlabs’ patented LFS (Low Force Stereolithography) technology to consistently deliver presentation-ready parts with crisp, accurate features and production-like surface finish. It is rich with features and sensors that improve ease of use and reliability so you can spend more time being creative and less time monitoring your printer.

Form 3B+

Rapidly fabricate accurate, high-quality patient specific anatomical models and surgical instruments with the Form 3B+, an advanced desktop 3D printer developed for all medical healthcare and dental professionals. Validated workflows tested medical experts across many specialties and disciplines means less trial and error in your practice or lab. Ideal for printing medical device prototypes, jigs, fixtures, moulds, and end-use parts, the Form 3B+ is compatible with the entire SLA materials library, including biocompatible, sterilizable materials.

Form 3L

The Form 3L is a large format 3D printer compact enough for the office – and robust enough for the factory floor. The larger size enables you to take control of large-scale part production by bringing it in-house, as well as enabling you to produce small batches of market-ready, high-quality parts. This is a cost-effective large format 3D printer that doesn’t compromise on the details, its two precision Light Processing Units inside the printer achieve consistent accuracy and detail across the entire build platform.

Form 3BL

The large format version of the Form 3B+ and developed for healthcare, this printer can produce full-size anatomical models at 1:1 scale, including paediatric and adult models, surgeon-specific or patient-specific surgical tools and much more. Tried and tested on thousands of printers, this fifth-generation stereolithography 3D printing technology provides a solid basis for dependable production. The Form 3BL is compatible with the majority of our SLA materials, including biocompatible, sterilizable resins made to ISO 13485 certified, in a FDA-registered facility. The Form 3BL is thoughtfully designed to maintain ideal print conditions with minimal operator intervention. You can remotely monitor and inspect your fleet of printers with the online Dashboard. The Formlabs automated resin system dispenses resin as parts print, and automated post-processing options make custom manufacturing easy. The Light Processing Units, rollers, and optics window can be replaced inhouse, so there is minimal down-time.

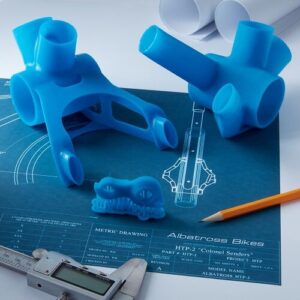

Fuse 1

With the introduction of the Fuse 1, Formlabs bring production-ready nylon 3D printing onto your benchtop with an affordable, compact selective laser sintering (SLS) platform. From print setup to powder recovery, our easy-to-use hardware and software are designed to maximize your efficiency at every step of the process. The need for inert gases and specialist air handling equipment associated with larger SLS platforms is eliminated as the powder gets exposed to elevated temperatures for a shorter period of time. The lower energy consumption means that it can run on standard AC power without requiring specialized infrastructure. The Fuse 1 features a patent-pending solution called Surface Armor, a semi-sintered shell that keeps the area around the parts evenly heated as they print, ensuring great surface finish, consistent mechanical properties, high reliability, and high refresh rates. Reaching and exceeding quality levels acceptable for industrial applications, this benchtop printer gives the user a highly efficient SLS 3D printer.

Printing in Formlabs’ own Nylon 11 and 12 powders unique to the Fuse 1, users can expect parts exhibiting fine detail along with high environmental stability and strength. Ideal features for functional prototypes and parts with complex geometries.

With reduced equipment cost, affordable material, and efficient powder recycling, the Fuse 1 is the smart choice for industrial quality SLS 3D printing.

CONTACT DETAILS

Advent 3D Ltd

Unit 14

Beaumont Business Centre

Banbury

Oxon

OX16 1TN

Telephone: + 44 (0) 1295 672600

Website: www.advent3d.co.uk

Email: information@advent3d.co.uk