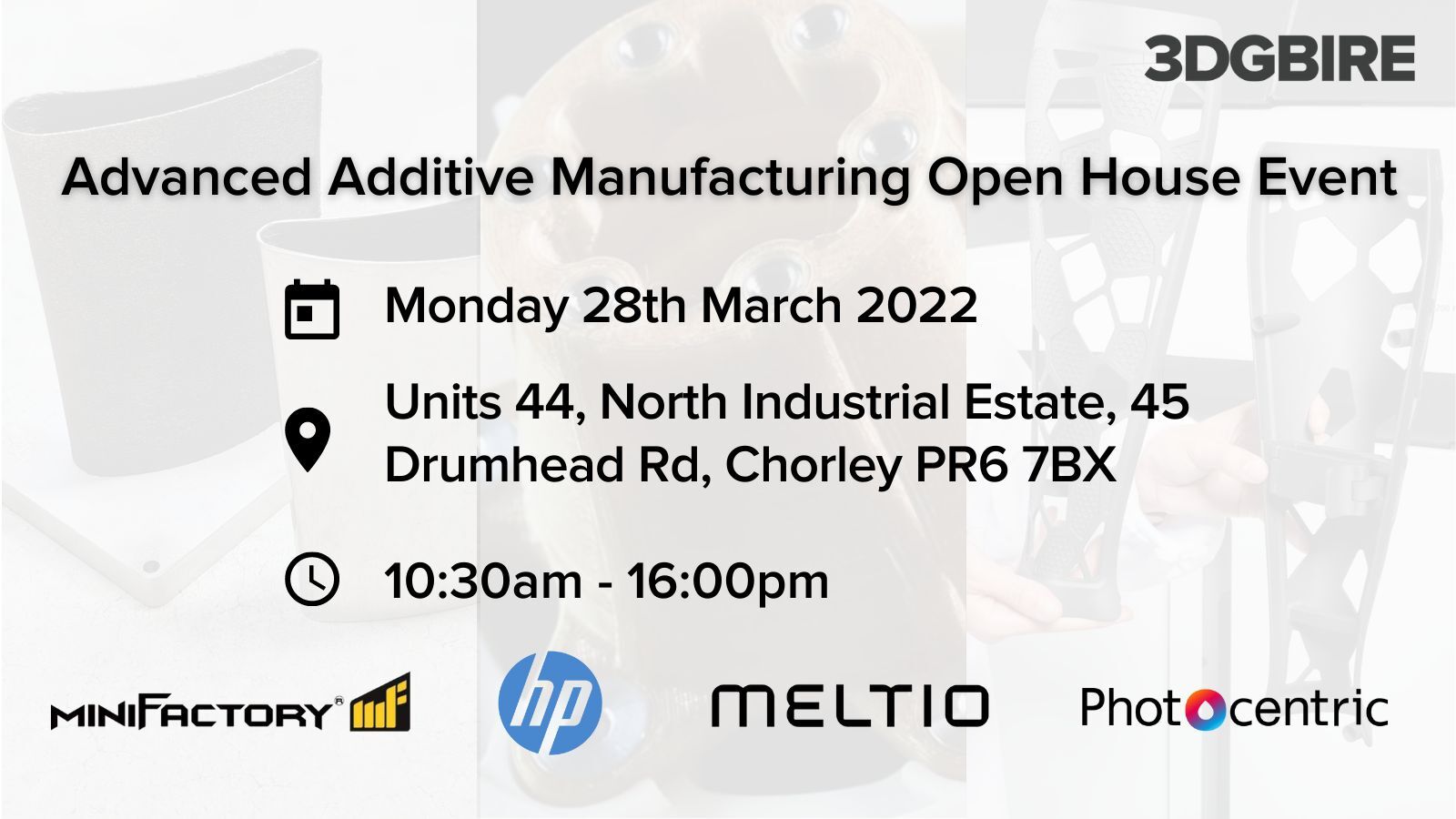

Don’t miss out on 3DGBIRE‘s Advanced Additive Manufacturing event where it will be joined by HP, miniFactory and Meltio on the 28th of March. Here, it will help you understand and learn more from the best and latest applications, materials and machines with live demonstrations, consultations and Q&A sessions.

HP Multi Jet Fusion 5200

The HP Multi Jet Fusion 5200 series enables you to produce a variety of cost effective, high quality end use parts as well as enabling mass custom manufacture. The MJF technology addresses sustainability objectives allow unused materials to be recycled through the system and local manufacture allows products with a lower carbon footprint.

miniFactory Ultra

The miniFactory Ultra is a one-of-a-kind industrial 3D printer that allows you to manufacture high-quality parts cost-effectively and quickly. Whether you need a single prototype or an extensive series of specific components, miniFactory’s 3D printing system lets you manufacture parts on-site using high-performance polymers and composites. Thus, you get the highest quality in the fastest production time and have more time to focus on the essentials!

Meltio

The most affordable large scale metal Additive Manufacturing solutions, the MELTIO Engine can be integrated with a robot arm to push the boundaries of conventional manufacturing. The Meltio integration is powered by Meltio’s LMD technology and with wire materials you benefit from its stability, affordability and ease of handling, as there is no need for specialised apparatus. The robot integration turns a traditional robot arm into a metal 3D printing system with no inherent size constraints, which is ideal for large and complex 3D printing.

The Meltio system can also be integrated with multi-axis CNC machines which will turn the solution into a fully hybrid manufacturing process, with industry leading multi-mateiral capability.

With the launch of the Meltio Materials range, Stainless Steel 316L, Stainless Steel 308L, Mild Steel ER70S, Titanium 64 and Nickel 718. The materials are extensively tested under controlled conditions with validated part properties and out-of-the-box optimised print parameters. Signed off by Meltio Metal Additive Manufacturing experts.

3DGBIRE offers personalised consultations, application design consultations, advanced AM training, lifetime technical support and even a print bureau service to support in peak times, to enable you and your business to get the most from these groundbreaking technologies!

Photocentric

The LC Magna delivers significant speed, volume and cost savings. The evolution of the LC Magna continues with a host of new features added, LCD printing and the LC Magna 3D Printer continues to represent the pinnacle of Photocentric’s product development. The versatility of the LC Magna supercharges product design enabling you to move from prototyping to production, in hours. With end use parts comparable to injection moulding, whether it’s a small batch, on demand or full production the LC Magna consistently delivers accurate end use parts at scale and is the essential choice for those seeking an agile and flexible solution for product manufacture.

Register to book your place now: https://bit.ly/Advancedam

Book a consultation: https://bit.ly/consultation3DGBIRE

Telephone: 01257 228411