When the Iowa State University (ISU) student team planned its entry into the 2016 American Society of Agricultural & Biological Engineers’ (ASABE) annual 1/4-sized tractor design competition, opting to use electronic throttle controls, they knew they were taking a risk. No previous entrant had ever used electronic controls before and, in the general agriculture industry, these types of throttles are found almost entirely on larger systems.

With the help of Thomson Industries, a leading manufacturer of electro-mechanical motion control systems, the team’s 12 engineering students discovered that their bold choice would set their tractor design apart from competitors and earn them points in design, innovation and performance.

Rising to the challenge

Each year since 1997, the ASABE has sponsored a ¼-scale tractor design competition, pitting agriculture engineering students against each other to push the limits of tractor design. Each competing team receives a 31–horsepower Briggs & Stratton engine, which must be left stock, and a set of two Titan tires for the rear of the vehicle. How the power gets from that engine to those wheels is entirely up to the students.

The primary objective of the ISU team was to enable the tractor to deliver power to each wheel individually. This, they reasoned, would optimize traction by compensating for changing soil conditions, something that is not possible with traditional hydro-mechanical drive systems. The team started by analysing a number of drive train options, including hydraulic, mechanical and electronic solutions.

They dismissed the option of using a hydraulic system, concluding that it would require a complex transmission assembly. They dismissed the purely mechanical transmission because speed control, overall and at each gear ratio, would be limited by the gears, unlike an electric drive train, where gear settings are essentially infinite, giving operators maximum flexibility to control speed. They also dismissed the mechanical option because it would not transmit power individually to each wheel, which their planned traction control system required. All things considered, the electronic drive train promised a much simpler and more elegant solution.

“Our calculations showed that an electronic drivetrain could be much more efficient than the hydraulic or mechanical technology because we could program it to change both speed and torque at each tire, sending as much or as little power to the wheels as needed to optimize traction,” said Clayton Hamilton, ISU team captain and recent agricultural engineering graduate. “Even if the operator went full throttle on the pedal, the motor controls would receive only the voltage they needed to maximize traction. This could also improve the turning radius by spinning the outside tire faster than the inside tire to give better maneuverability as well.”

System design

The ISU design couples a DC electric generator to the engine. The generator powers a motor at each rear wheel, which accepts only a certain range of voltage to maintain optimal traction. Too little voltage and the tractor will not move; too much voltage and the wheels will slip and lose traction. The challenge was to figure out how to control engine speed so that the generator produces optimum voltage.

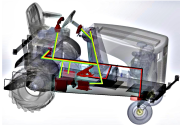

Figure 1 shows the schematic of the ISU design, with electronic components shown in red. Reading left to right, the tractor motor (M) powers the generator (G), which transmits current to the controllers. These control motors at each wheel are shown in the lower right portion of the diagram. In the upper right hand section of the diagram are the circuits powering a joystick, display and the controller (foot pedal).

Figure 1 shows the schematic of the ISU design, with electronic components shown in red. Reading left to right, the tractor motor (M) powers the generator (G), which transmits current to the controllers. These control motors at each wheel are shown in the lower right portion of the diagram. In the upper right hand section of the diagram are the circuits powering a joystick, display and the controller (foot pedal).

The foot pedal controls engine speed, while the operator controls the propel speed with the joystick, which allows management of the speed at each of the rear wheels. Making this work requires a highly precise means of engine speed control to produce the optimal voltage for the electric drivetrain, which is essentially the function of an electro-mechanical actuator. Fortunately for the team, Thomson Industries, a leading supplier of electric linear actuators, was among the event sponsors and was more than happy to provide the team with advanced electro-mechanical actuation technology.

“Thomson has been designing and manufacturing electro-mechanical linear actuator solutions for large agricultural and construction vehicles for 50 years,” said Chad Carlberg, product line manager for linear actuators at Thomson. “We were excited to see the ISU team’s interest in driving innovation at this year’s ¼-scale tractor competition and honoured that they chose to accomplish this with Thomson linear actuators. We also look forward to what they come up with next year.”

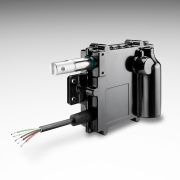

Thomson provided the team two sample actuators to evaluate. One was its rugged Max Jac® linear actuator, a compact high-power density model designed specifically to operate and thrive in some of the harshest environments typical to mobile off-highway equipment. The other, its Electrak Throttle linear actuator, is primarily found in applications requiring throttle control of a mechanical engine. The ISU team chose the Electrak Throttle because it provided the precise motion and force required for their application.

In operation, position feedback devices on each motor signal the travel speed and propel mode to the operator display via a CAN bus network. The display also shows engine speed and hours.

In operation, position feedback devices on each motor signal the travel speed and propel mode to the operator display via a CAN bus network. The display also shows engine speed and hours.

Dynamic readouts in the display correlate motor speed with the joystick position and flash a warning when the positions don’t match, indicating less than optimal traction. Based on this information, operators can adjust the joystick position, or the actuator will change engine speed to provide optimal power to achieve desired traction.

Taking the field

The 2016 ASABE competition took place at the Expo Gardens Fairgrounds in Peoria, Illinois. The ISU team joined 25 other hopefuls, who would be competing on the attributes of the tractor itself, their ability to justify design choices and, ultimately, the actual performance.

The day began with the technical inspection during which judges confirm compliance with the rules. They check hitch height, brakes stand, overall size, wheel base, schematics, safety features and other design features. Although the rules committee had approved the use of an electric drivetrain in advance, it was not until the technical inspection that the rest of the competitors learned of ISU’s unique strategy, which took many by surprise. Throughout the judging, the electric system proved to be a formidable competitor.

Its first triumph was in the sound test. Rules restricted sound levels to less than 90 decibels. The precision with which the ISU team could hold the engine at optimal operating levels meant they could operate at fewer RPMs, bringing their entry to between 78 and 80 decibels. No one else was even close. Their electric drivetrain implementation also drove them to the top rankings in overall innovation and safety, and it put them in the top 10 for manufacturability and serviceability.

Contributing to ISU’s scores in manufacturability was the fact that all components could be bought off the shelf, reducing the need for costly machined housings and other custom components. Eliminating the need for hydraulic tubing also enabled a modular construction strategy, so that a manufacturer could assemble front, back and operator stations in separate areas and join them together easily in a final step. This is not possible when tubing is extending across the length of the equipment. Removing tubing also won them serviceability points by not having to replace hydraulic fluid or deal with cleaning oily components.

In addition, judges were impressed by the physical manifestation of the design, awarding top marks for how well the team described its process and design justification in writing, and second place in how they presented their solution to a panel simulating a potential manufacturer’s evaluation process.

Maneuverability and pulling success

The team was also pleased with its successes in the maneuverability and load pulling portions of the competition. Maneuverability is measured by the effectiveness with which an operator can guide the machine through a course consisting of an arrangement of posts without disturbing the golf balls delicately balanced on the ends of the posts. The ISU team scored in the top 10 in this category and attributed that mostly to the differential control of the back tires.

The team was also pleased with its successes in the maneuverability and load pulling portions of the competition. Maneuverability is measured by the effectiveness with which an operator can guide the machine through a course consisting of an arrangement of posts without disturbing the golf balls delicately balanced on the ends of the posts. The ISU team scored in the top 10 in this category and attributed that mostly to the differential control of the back tires.

The pulling competition measured the length to which the tractor can pull a weighted sled down a dirt track. Tractors usually produce 2000 to 3000 pounds of force while pulling the sled. In last year’s competition, using a system with a hydraulic transmission, the team pulled the sled 197 feet (60 meters). This year, given that they were introducing new technology, they would have been happy pulling it more than 100 feet but exceeded that dramatically with a pull of 207 feet. It was a respectable performance compared to the farthest pull of the day of 260 feet (79 meters).

All in all, the move to the electric drivetrain paid off well for the ISU team, garnering first place finishes in sound level, innovation, safety and written design, second place in presentation, with top 10 positions in manufacturability, serviceability and maneuverability, and out-pulling its previous entry.

The ISU tractor’s core technology will ride again in the next ASABE competition in June 2017. In the tradition of the annual event, each school will enter two tractors, an improved version of the previous year’s entry and a new design. Thomson has already agreed to provide electro-mechanical actuator technology to the next project, so when ISU once again fields the electronic throttle, it will come as no surprise. The only surprise may be how well the team builds on what is already an impressive foundation of success.

The ISU tractor’s core technology will ride again in the next ASABE competition in June 2017. In the tradition of the annual event, each school will enter two tractors, an improved version of the previous year’s entry and a new design. Thomson has already agreed to provide electro-mechanical actuator technology to the next project, so when ISU once again fields the electronic throttle, it will come as no surprise. The only surprise may be how well the team builds on what is already an impressive foundation of success.