The first quarter of 2014 is almost complete and whilst the company has maintained a high order book, key purchases have been made which we want to introduce to you.

The first quarter of 2014 is almost complete and whilst the company has maintained a high order book, key purchases have been made which we want to introduce to you.

Our original Wenzel CMM, LH 54, has been moved on to the shop floor next to the 2 Phauter Gleason auto loading CNC hobbing machines to aid rapid in house inspection. Our new Wenzel WGT280 has been placed in the Inspection Room as our main CMM, but has the added benefit of a tailstock and larger checking capability. Both CMM’s have gear measuring software for graphical presentation achieved by Renishaw continuous contact probing.

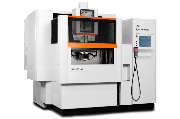

Gibbs Gears has just purchased a 300mS Agie Charmilles Wire Cutting machine to aid low to medium volume, high value parts, where it will complement conventional machining to meet high accuracy customer requirements. The Company will report the benefits after installation and initial production from April 2014.

Gibbs Gears has just purchased a 300mS Agie Charmilles Wire Cutting machine to aid low to medium volume, high value parts, where it will complement conventional machining to meet high accuracy customer requirements. The Company will report the benefits after installation and initial production from April 2014.

Having made a significant investment in our Phauter Gleason CNC Shaping machine, it has been tooled with top of the range work holding from Hainbuch in order for tight limits to be achieved through various holding mechanisms. The machine is instrumental for fast cutting internal and external straight and helical forms; the latter utilising its programmable guide.

Gibbs Gears has taken on an apprentice Sales Engineer. Beau Garrod has been instrumental in the marketing campaign by setting up and maintaining accounts with Twitter, Pinterest, Google Plus, Linked In and You Tube. A Facebook account will be opened in April 2014, so every modern contact method is open to keep in touch.

Gibbs Gears has taken on an apprentice Sales Engineer. Beau Garrod has been instrumental in the marketing campaign by setting up and maintaining accounts with Twitter, Pinterest, Google Plus, Linked In and You Tube. A Facebook account will be opened in April 2014, so every modern contact method is open to keep in touch.

Gibbs Gears looks forward to supporting your current and future projects, so if you prefer to e-mail your enquiries, please send them to sales@gibbsgears.com

For further information and view our presentation video, please go to our updated website www.gibbsgears.com