From January 1st 2015 the latest efficiency regulations for electric motors come into force in Europe whereby any new installation using a motor between 7.5 kW and 375 kW must use either an IE3 rated motor or an IE2 motor installed with a variable frequency drive (VFD). Aimed at improving the overall efficiency of the installed equipment across Europe, the regulation is supported by a new standard, EN50598, which benchmarks the efficiency ratings of electric motor drives.

From January 1st 2015 the latest efficiency regulations for electric motors come into force in Europe whereby any new installation using a motor between 7.5 kW and 375 kW must use either an IE3 rated motor or an IE2 motor installed with a variable frequency drive (VFD). Aimed at improving the overall efficiency of the installed equipment across Europe, the regulation is supported by a new standard, EN50598, which benchmarks the efficiency ratings of electric motor drives.

EN50598-2, will widen the focus from a single component to the efficiency of the complete power drive system (PDS). The new efficiency classes (IES) provide a structure that allows the losses for a complete drive system to be compared. The median range is IES1 and systems which fall below the minimum value of IES1 are classed as IES0. More efficient systems, with values 20% above IES1, are identified as IES2.

This new standard will also help end users to gauge payback periods more accurately. Previously, the overall efficiency of speed controlled motors was estimated using rough energy consumption figures. Now, with verified efficiency curves, the payback period for a motor/drive combination can be calculated more realistically.

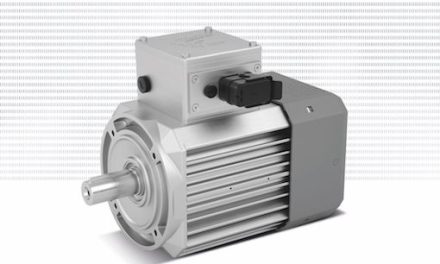

Bauer Gear Motor has always aimed to keep one step ahead in terms of design and efficiency with its complete range of IE3 motors already in the marketplace, including all those between 0.75 kW and below 7.5 kW which meet the regulations due to come into force in January 2017. All of the motors manufactured by Bauer are at least IES1 ready and its experienced engineers can provide expert assistance in equipment selection.

The exceptions according to the regulation (EC) 640/2009, namely brake motors and those operating in potentially explosive atmospheres, will retain their exempt status. However, Bauer has developed the S series of permanent magnet synchronous motors (PMSM) which offers variable-speed motors in efficiency class IE4 for use in explosion hazardous areas.