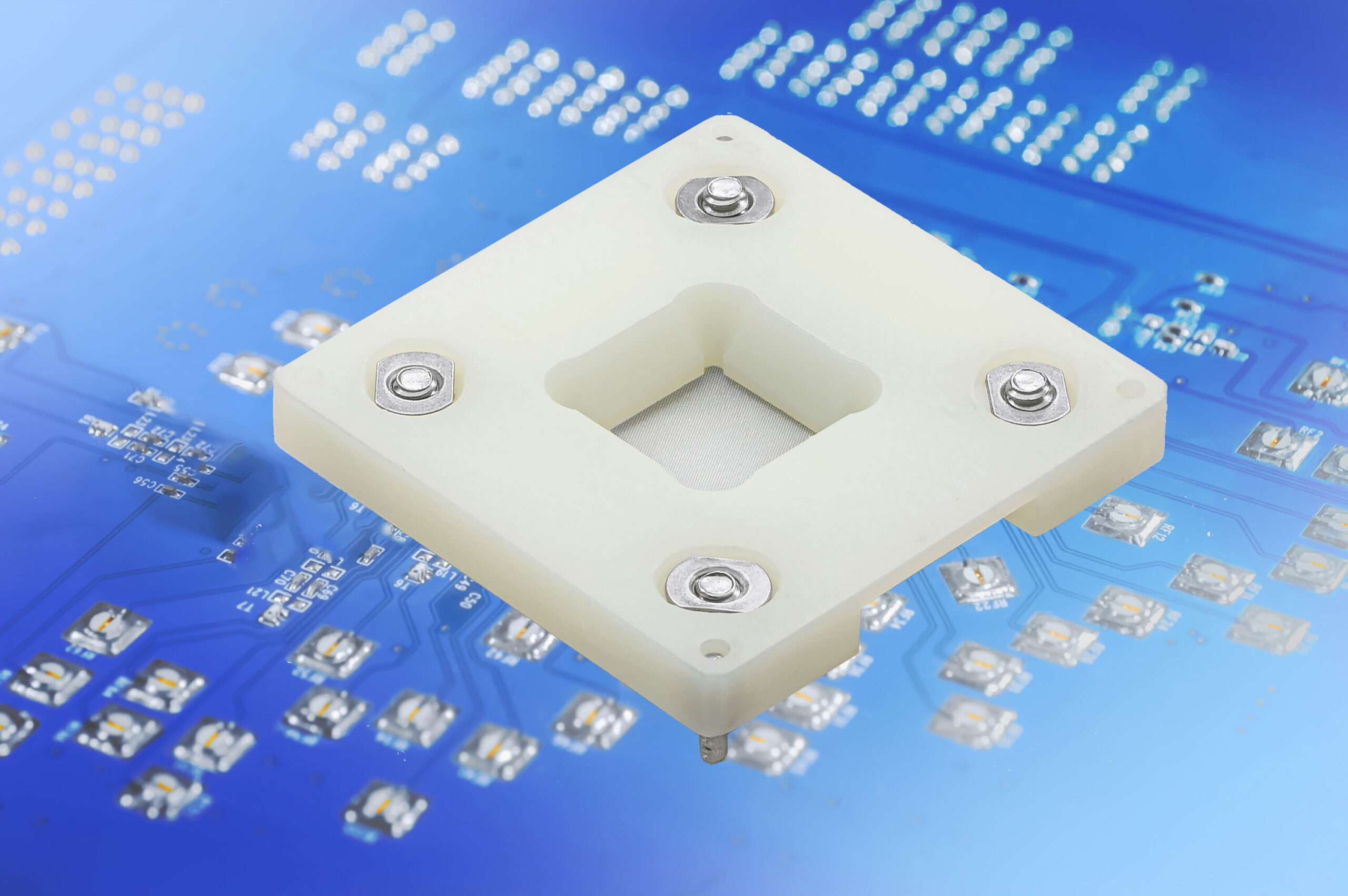

![]() Smiths Interconnect, a leading provider of innovative solutions for semiconductor test applications, has announced its new Galileo test socket for Area Array and Peripheral Package Test.

Smiths Interconnect, a leading provider of innovative solutions for semiconductor test applications, has announced its new Galileo test socket for Area Array and Peripheral Package Test.Galileo is an innovative, low–profile test socket engineered to support today’s high performance Digital and RF applications. It leverages proven interposer elastomer technology and advanced 3D printing manufacturing to provide a high-performance solution for BGA, LGA, QFP, SOIC, or QFN packaged devices with extremely short lead times.

“A good portion of customers have products with critical time–to–market (TTM) goals. When speed is what they need, the Galileo test socket provides an accurate, at-speed and cost-competitive test solution. Given the efficiency it provides, we have named the product after the Italian physicist and engineer, Galileo who made a significant contribution to speed and velocity studies”, said Bruce Valentine, Vice President and General Manager of the Semiconductor Test Business Unit at Smiths Interconnect.

Using a unique “universal” elastomer contact assembly, Galileo supports almost any standard package pinout, on any pitch (or multiple pitches) at >0.35mm, in any configuration, with no extra tooling charges. A single socket can be re-used across multiple pitches and pad/ball placement. In addition, no contact alignment or registration holes are required in the PCB, enabling quick and easy board integration.

Galileo elastomeric test socket offers the following features:

• Extremely short electrical paths to deliver excellent signal integrity

• Low inductance, high bandwidth >40GHz

• High Current Carrying Capacity

• Very high thermal conductivity

• Field-replaceable contact set with minimal tooling and technical expertise required

• 3D printing technology for quick-turn socket body manufacture

• Pre-stocked elastomer sheets enabling very short lead-times

• Solder–down performance for applications where signal integrity loss is not an option