Meeting military spec demands and the tough conditions faced at sea, polycarbonate enclosures from Spelsberg have been selected to protect the electrical connections on two new aircraft carriers – the HMS Queen Elizabeth and HMS Prince of Wales – which are currently under production

Meeting military spec demands and the tough conditions faced at sea, polycarbonate enclosures from Spelsberg have been selected to protect the electrical connections on two new aircraft carriers – the HMS Queen Elizabeth and HMS Prince of Wales – which are currently under production

Under one of the most significant naval investments made by the Ministry of Defence since the turn of the century, BVT Surface Fleet Solutions is currently building two of the world’s largest aircraft carriers for the Royal Navy – the HMS Queen Elizabeth and the HMS Prince of Wales. The HMS Queen Elizabeth, which will be the first of the QE class carriers to be finished, is due for completion in 2016.

A vital component of modern naval strategy, aircraft carriers act as mobile landing strips for aircraft, allowing them to access parts of the world that they wouldn’t usually have the rangeto reach. The two new carriers will each require 40,000 tonnes of steel and will weigh approximately 65,000 tonnes. Their power stations will generate 110MW and over 1.5 million metres of cable will be used across each carrier.

Once at sea the ship’s engineers will have extremely limited access to spare parts, so the components specified need to perform reliably while withstanding the harsh environment. So, to protect the electrical connections in the maritime environment, the junction boxes needed to be tough, provide suitable ingress protection and offer corrosion resistance from the abrasive salt particles. In addition, as the components may be subjected to constant vibration which would loosen screws, the lids needed to be secured with an alternative method.

Being a military spec project, it was expected that metal junction boxes would be considered, however not only would these be more likely to corrode but they would be prone to denting during collisions. Weight saving was another consideration – it may seem strange to worry about the weight of a junction box on a 65,000 tonne aircraft carrier, comments Spelsberg, but the ship builders are aware that combined weight savings over all the onboard components across the entire span of the ship can result in very real performance improvements. Reduced weight will also result in lower delivery costs and improved installation times.

Chris Lloyd, general manager at Spelsberg commented: “When we first spoke to the ship builders it quickly became clear that a tough, polycarbonate solution would be more suitable.”

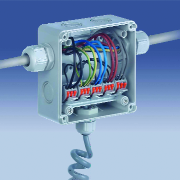

To meet the requirements, Spelsberg UK recommended its polycarbonate, IP65 Abox enclosure. By supplying the enclosures assembled, including terminals, the company was able to help greatly reduce on-site installation time.

Lloyd added: “It’s fantastic to be involved on such a large project and we are very proud that our products have met all the Ministry of Defence standards required for lighting circuits below decks.”

Suiting the application

The Abox range is made from halogen-free materials and is available with a vast array of specifications in terms of size, IP rating, gland type and terminal type, suiting most applications – from the Abox 025, measuring just 80mm x 80mm right up to the Abox 2400 with dimensions of 640mm x 320mm. A red cover can also be specified to identify circuits for safety lighting.

The industrial quality (IQ) versions of these junction boxes have an IK08 rating for protection against mechanical stress and the range is available with a variety of accessories which allow termination of cables with cross sections from 1.5mm2 up to 240mm2. The SL series of Abox, equipped with the screwless terminals, are approved for use on ships and in offshore applications by Lloyds Register, which was crucial in the specifications offered to the client.

The range is built with at least eight potential cable entry points and has a number of accessories which can be specified, including various terminals, cable clamps, glands, mounting rails and plates as well as sealing kits. For applications where the enclosure may be fully submerged a cast resin sealing kit is available which provides IP68 protection up to 15m.

Spelsberg els UK

T: 01952 200716