Parvalux has installed a new solid machine prototyping service, ensuring that a ‘proof of concept’ of a geared motor can be delivered to a customer with a quick lead-time.

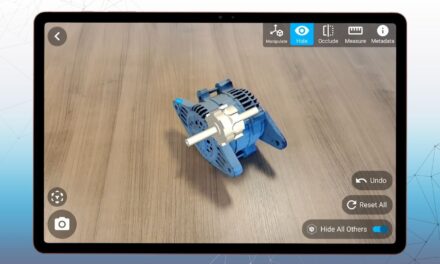

Acting as the customer’s design resource, the twenty-strong Parvalux engineering team quickly produces a detailed 3D model of the gearbox casing. The design is then sent to a dedicated 4-axis CNC machine, which is used exclusively for prototyping. The machine allows a fully functional solid prototype to be produced in as little as two days.

Dr Martin Mathias, technical director, believes that the new prototyping machine, has already delivered a return on investment by dramatically reducing lead times for Parvalux customers.

“The benefit of these technologies is that a ‘proof of concept’ can be manufactured in literally days and at low cost. This will greatly help customers who need to identify a product solution when working to a tight deadline on an application.”

The service is perfect for delivering geared motor prototypes to power applications in a wide range of industries.

Contact: sales@parvalux.com