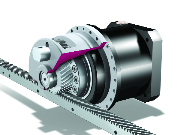

STOBER has developed a new concept for a super compact and highly efficient rack and pinion drive systems. With the HighForce ZTRS rack and pinion drive, the integral output bearing housing is a stiff supporting assembly for the pinion which relieves the moment load on the gearbox output bearings. The reduced tilting moment makes it possible to base the drive design on the torque required for the machine operation.

STOBER has developed a new concept for a super compact and highly efficient rack and pinion drive systems. With the HighForce ZTRS rack and pinion drive, the integral output bearing housing is a stiff supporting assembly for the pinion which relieves the moment load on the gearbox output bearings. The reduced tilting moment makes it possible to base the drive design on the torque required for the machine operation.

As a rule this means that the gear unit can be a size smaller than normally used. Due to the small pinions, a higher output speed is required which means that the gear ratio can also be lower and in many cases a single-stage planetary gear unit can be used instead of a two-stage.

The new mounting system makes it possible to use rack pinions with a small number of pinion teeth, which can increase linear stiffness by up to 100%, and reduce linear backlash by around 40%. The wide variety of gear ratios and pinion sizes allows optimised adaptation of the inertia. The ZTRS rack and pinion drive system is available from modules two to six.

STOBER Drives www.stober.co.uk

T: 01543 458858