The structural material of field equipment enclosures is critical. While some trends can be satisfied with any of the usual materials – metal or GRP/glass fibre reinforced polyester are used commonly, or thermoplastics for some applications – meeting the new challenges with bent-metal enclosures is becoming increasingly difficult. Martin Hess & Gavin Faulkner of Intertec Instrumentation consider some trends, and the generic values of using GRP for future high-performance outdoor protection

The structural material of field equipment enclosures is critical. While some trends can be satisfied with any of the usual materials – metal or GRP/glass fibre reinforced polyester are used commonly, or thermoplastics for some applications – meeting the new challenges with bent-metal enclosures is becoming increasingly difficult. Martin Hess & Gavin Faulkner of Intertec Instrumentation consider some trends, and the generic values of using GRP for future high-performance outdoor protection

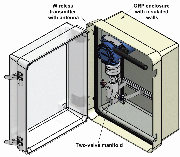

Walk around a refinery and the field enclosures and cabinets look much as they did 20 years ago. It’s easy to think that it’s a well understood technology with little change, but this is far from the case. For instance, the key applications that drive a lot of this environmental protection business – particularly oil and gas – are demanding new features, such as higher energy efficiency and wireless-friendly features.

By and large, the ‘easy’ oil and gas fields have all been found. The search for new resources now takes place in much harsher environments: deep water, the remotest deserts, and the most hostile latitudes. Along with that trend, more processing facilities are being built where resources are located. Instrumentation will often be exposed to corrosive chemicals such as sulphur, chlorine or salt. It’s a tough challenge as even 316 stainless steel can corrode in such environments (the influential NORSOK standard recognises this, for example).

For manufacturers of sheet metal-based enclosures, it has led to specifications such as acrylic painting with minimum coating thickness. In contrast, GRP is almost immune to the corrosive effects of salt and aggressive chemicals. Reduction in GRP thickness is almost negligible when exposed to most petrochemicals, even when measured over very long periods (decades and more). Only a very few specialised chemicals pose problems for GRP, and in general the material is highly suited to long lifecycle field protection applications.

Safety and standards

Another key focus today is human and environmental safety, which has become a huge issue following recent hydrocarbon leakage and fire/explosion incidents.

A common new demand is for enclosures to be blast-proof. High pressure waves can easily damage and break bent-metal or thermoplastic. GRP, however, has intrinsic flexibility, allowing the enclosure, cabinet or shelter to flex and absorb blast-wave forces. Such enclosures are typically fabricated using ‘sandwich’ panels with GRP sheets enclosing an inner core, providing insulation and further strength. The manufacturing process does not rely on moulds, so the thickness of the inner layer can easily be varied to provide the strength required for particular applications. This is not possible with solid plastic enclosures fabricated using injection moulding – as they would require new moulds in order to vary the properties. Similarly, applications that must withstand seismic events can also be made easily using custom sandwich style GRP construction.

Most common safety needs are typically covered by standards, with explosion proof regulations being key – but these standards are continually evolving. One interesting recent example is a minor change to IEC 60079-0, the base standard for electrical installations in hazardous areas, that specified that climate testing now has to be done before other testing (IP rating, impact, etc). This turns out to be a real challenge because of the general trend towards operations in harsher climates.

Most common safety needs are typically covered by standards, with explosion proof regulations being key – but these standards are continually evolving. One interesting recent example is a minor change to IEC 60079-0, the base standard for electrical installations in hazardous areas, that specified that climate testing now has to be done before other testing (IP rating, impact, etc). This turns out to be a real challenge because of the general trend towards operations in harsher climates.

If, for example, an enclosure is destined for Siberia then it might be tested to -65 and +85°C. These temperatures are so extreme that they can change the properties of the material – a thermoplastic-based enclosure, for example, would become very brittle. Not only does GRP remain stable even down to -100°C, but it retains good properties in high temperatures too – so much so that GRP is highly suited to creating fireproof cabinets for protecting critical valve actuators.

Another example is IEC 60079-10, which now defines ventilation requirements more clearly. Ventilation is essential in order to avoid condensation and guard against any build up of explosive atmosphere. Of course, ventilation is at odds with the general need for field enclosures to have the appropriate IP rating to protect against the ingress of dust and liquids. Careful use of breathable membranes has provided the means to accommodate ventilation and drain points to meet the new definitions.

Insulation matters

The general need to avoid condensation touches on another challenge, the demand for higher energy efficiency. When positioning the contents of the enclosure and any heating system to keep the interior above the dew point – or protect against freezing – it’s important to avoid creating cold spots, as this is where the condensation will appear. Careful layout is one aspect of minimising energy usage, for example by positioning internal components close together and maximising the insulation benefit of the surrounding air.

Another trend is better enclosure insulation. Few off-the-shelf metal enclosures are available with the appropriate insulation to minimize the temperature regulation problem. In any event, just adding insulation is rarely adequate, because of fundamental limitations posed by the metal construction. Heat losses are exacerbated by the conducting properties of metal, and often by the typical sorts of metal bulkhead fittings used to mount such enclosures as well – which can act as rudimentary fins. Moreover, designers almost invariably need to cut access holes – worsening heat loss substantially and creating cold spots. If insulation is used, it is often rudimentary – such as wrapping mineral wool around the tube or cable. Ideally, purpose-made insulation components need to be used and these tend to be specialist items that are not readily available.

Starting a field protection application with the right enclosure material makes a big difference to the efficiency of protection. Polyurethane foam (thermal conductivity: ? = 0.02 W/m K) is typically used for insulation in ‘sandwich’ GRP panelling, in thicknesses from 20-100mm – providing a thermal transmittance or ‘k’ factor of around 1.2 to 0.2 W/m2K. (Galvanized or stainless steel enclosures are made of materials with high thermal conductivity: ? = 15–50 W/m K.)

Insulation makes a big difference. To maintain the same internal temperature, insulated enclosures typically require just a sixth of the heating power of uninsulated enclosures. Well considered insulation practice will also save additional energy by providing a very stable temperature profile – with no wild swings between ‘heater off’ and ‘on’ situations. Again, careful layout helps – for example, by minimising the difference and temperature gradient between top and bottom of the components.

Insulation makes a big difference. To maintain the same internal temperature, insulated enclosures typically require just a sixth of the heating power of uninsulated enclosures. Well considered insulation practice will also save additional energy by providing a very stable temperature profile – with no wild swings between ‘heater off’ and ‘on’ situations. Again, careful layout helps – for example, by minimising the difference and temperature gradient between top and bottom of the components.

Same rules for cooling

Of course, insulation is just as important when designing enclosures for cooling purposes. Here, the drive to slash energy consumption has led to an upsurge in demand for passive cooling, which has been well proven over the last decade for outdoor applications. What is not so well known about the technology is that the performance and choice of passive cooling systems has also developed. Many still think that passive cooling is only suitable for arid climates, with their large swings between day and night temperatures; and that systems are large – requiring big tanks for the water coolant.

This is how this industry segment established itself, but it does not give the full picture today.

New techniques to create ‘hybrid’ systems with forced circulation of media using small pumps, or to add a chiller unit to cool water at night (e.g. for larger requirements such as analyser shelters), provide interesting new design possibilities. In a nutshell, they provide ways to downsize environmental protection systems – and decrease maintenance.

Going wireless?

One emergent advantage of using GRP is that enclosures provide a benign environment for housing new generations of wireless-enabled field instruments – extending their applications potential in outdoor locations. The GRP (and foam insulation, and any supporting struts inside which are also made from GRP) do not damp electromagnetic signals. Importantly, they allow the antennas of wireless-equipped instruments to remain inside the enclosure.

A metal enclosure would probably force a user to install the antenna externally. This adversely affects the bill of materials and system building costs, but it also places a delicate object in a location where it can be damaged. Enclosures for processing plants are typically specified to protect against impacts – and with good reason. For instance, we were asked to design a protective solution for a refinery that shut down because a falling object activated a safety switch.

The potential for ongoing maintenance costs – and possibly a partial or full process shutdown because of an instrument failure – provide an important reason to select GRP enclosures. Given the long lifecycles of most outdoor instrument enclosures it’s definitely worth thinking about wireless connectivity at the specification stage – even if you have no current plans for wireless communications. With planning it would be easy to ensure the complete enclosure (including mounting rails, etc) is non-metallic. This could save enormous costs, allowing simple plug-in changeovers from cabled to wireless field communications at some future point.

Engineering know-how

The evolving nature of field protection has led to substantial growth in demand for turnkey enclosures.

Choosing an expert partner can help companies to solve both current needs and pave the way towards easy evolution of control and instrumentation networks.

INTERTEC Instrumentation

T: 0800 756 1102