Objectives for today’s machine designers are increased efficiency, improved reliability and increased final product quality, and this was exactly the case when Foila International worked with the chartered designers Pemberton Dear and the design team from Rotalink to develop Foila Baby, an automated, foil preparation machine for hair colouring. The machine is said to save hair colourists substantial preparation time by dispensing consistent and repeatable aluminium foil strips from a roll by cutting it to a specified length with a varying number of folds.

Objectives for today’s machine designers are increased efficiency, improved reliability and increased final product quality, and this was exactly the case when Foila International worked with the chartered designers Pemberton Dear and the design team from Rotalink to develop Foila Baby, an automated, foil preparation machine for hair colouring. The machine is said to save hair colourists substantial preparation time by dispensing consistent and repeatable aluminium foil strips from a roll by cutting it to a specified length with a varying number of folds.

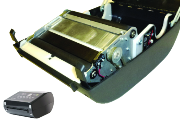

The machine, however, had to be compact, simple, cost effective, reliable, and capable of withstanding the salon environment where it would be faced with heat, humidity and chemicals. So, the final design centred on a stepper motor to increment the foil roll through a pinch roller mechanism, a brushed DC motor and gearbox with a built-in mechanical clutch for the fold, and a DC motor/gearbox to drive a guillotine which cuts the foil to length. For folding and cutting the foil. Rotalink’s compact 222 series gearboxes were selected, which have a four-hole mounting which is said to provide higher stiffness, increased torque and smoother speed than two-hole ovoid alternatives. The gear design, using engineering polymer spur gears, also contributes to the quiet operation of the machine. A mechanical clutch was selected to provide feedback to closely control the torque for the fold axis. The clutch limits the amount of force applied to the foil material when producing a crease prior to folding, but ensures the material is not damaged.

Foila Baby’s functional design also includes a simple membrane keypad and digital display.

Rotalink

T: 01460 72000