Needing to ensure the safety of both employees and workpieces, a paint shop designer selected Murrelektronik’s MVK Metal Safety fieldbus module.

Paint shops are typically made up of many different machines – such as conveyors, lifts, handling stations, automated gantries, technical process applications for chemical preparation of produced items, powder and/or wet coating areas, as well as ovens for heat treatment. But while these days it’s not very difficult to design an automated paint shop, the challenge lies in designing one that meets customer expectations for both the process and functionality while also complying with all safety regulations. This was the case for Polish company ADAL when it was carrying out one of its latest projects.

Considerations

The new paint shop has the ability to coat three different groups of item widths as well as two groups that require different periods of heating in the oven. Added to this, there are:

• Several types of processed materials, including mild steel, galvanised steel, aluminium and cast iron

• Two types of surface preparation – realised in a 14-tubs spray/immersion washer

• Three types of coating techniques – cataphoretic coating, powder coating and a mix of both

• A wide range of powder colours

• Priority modes for express orders.

While there are high levels of automation here, human supervision is necessary to operate and control the individual processing cells. As an example, a technician has to take samples directly from a tub several times each day, while automated gantries carry metal items over his head. The operator must also check if the automated cleaning of a powder coating chamber is done properly.

Such situations require precise safety regulations for both the technicians and the workpieces. However, the process cannot be stopped or paused for too long because the coated parts could get damaged or become useless. So, a reliable fieldbus module that would allow ADAL to successfully complete the project while prioritising safety was needed.

The solution

The control units used in the paint shop are S7-1500 PLCs, one of which is an F-PLC. All of the devices are using Profinet which, due to PROFIsafe, allows the combination of standard and safety components in one network.

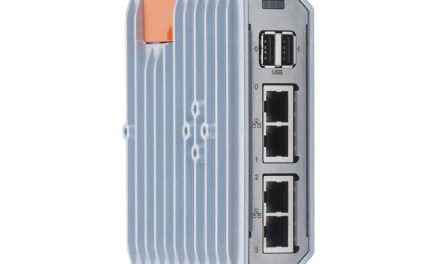

Due to the size of the installation – it is almost 100 x 60m – and the high distribution of safety signals, ADAL decided to use Murrelektronik’s MVK Metal Safety modules for safety I/Os.

The types of sensors used in the application is diverse, ranging from limit switches, guard-locks and light curtains, to E-stop buttons. MVK Metal Safety allows all of the sensors to be easily connected and implemented. Safety outputs are mainly used to stop the drives and cut off air pressure, and several types of SEW distributed drives were used in the project. The STO inputs of the drives were used or a safe stop SS1 was realised, depending on the type of operation of the drive.

Using the MVK Safety modules from Murrelektronik enabled ADAL to control all of the signals, consolidate the amount of hardware used, and reduce wiring and installation costs.

The MVK Safety modules were also used in automated gantries controlled over wireless communication. Both control and safety information are transferred over Wi-Fi and there was no need to build a separate system for safety signals.

T: 0161 728 3133