A new approach to measuring the displacement of hydraulic cylinders has been jointly developed by Micro-Epsilon and Sensor-Technik Wiedemann.

A new approach to measuring the displacement of hydraulic cylinders has been jointly developed by Micro-Epsilon and Sensor-Technik Wiedemann.

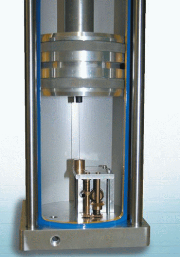

The solution is based on a draw-wire sensor, which is integrated inside the cylinder at the bottom, where it is protected from external influences. The measuring wire is attached to the bottom of the piston. One challenge here was the design of the sensor and the signal routing to the outside, as a bore hole in the cylinder housing is always a weak point. Pressures are up to 600bar in the cylinder and leakage must be prevented.

Each movement of the piston causes a rotation of the wire drum, which is divided using a gearbox onto two shafts with different rotational speeds. A magnet is positioned on each shaft at the bottom of the cylinder, whose positions can be measured by external, magnetic angle sensors. Using a suitable gearbox, each combination of the magnet position only occurs once across the complete measuring range. The sensor therefore shows the characteristics of an absolute encoder.

Due to the high pressures, the cylinder walls must be constructed from relatively thick metal, but a magnetic signal transmission through these is not suitable for measurement requirements. However, a solution was found for this without having to weaken the cylinder design. At the points where the two gear shafts reach the bottom of the cylinder, the steel is tapered and a special membrane is welded on. Using this, a magnetic signal can be transmitted with sufficient quality. Using FEM calculations, the minimum possible wall thickness was determined.

The electronics on the outside were designed to be extremely flat and can easily be attached to the bottom of the cylinder. Due to the draw-wire sensor, the system can easily be adapted to different cylinder lengths and diameters and to a range of operating conditions.

According to Micro-Epsilon, its wireSENSOR WDS-TZ10 is suitable for cylinders that have a lifting height between 0.5m and 15m. Cylinders with this type of displacement measurement are ideally suited to harsh environments and in mobile construction machinery and off highway vehicles, explains the company. For short cylinder strokes, the TZ10 can be used with the magnetostrictive method.