For a number of decades, digitalisation, robotics and automation have produced significant benefits for manufacturing. The construction industry, however, is only just picking up on DfMA (Design for Manufacture and Assembly) for repetitive mass production of standardised components.

Rather than design components and have them made in remote factories to be delivered and then assembled on-site, Newtecnic facilitates the use of Construction Labs where local skilled craftspeople, using locally sourced materials, deploy very advanced production machinery in temporary factories. These small but efficient manufacturing cells are dedicated to producing mass-customised components. And, as robots become more advanced, they will interact with these Construction Labs – generating, moving and installing both new and replacement building parts.

Large-scale projects that Newtecnic is currently partnering on have been specifically developed to facilitate the use of robots and automation. For example, the King Abdullah Financial District (KAFD) Metro Hub in Riyadh, Saudi Arabia, was engineered by Newtecnic for maintenance by robots and with future on-site component production very much in mind. The company is currently overseeing construction of the building envelope where it will examine and approve the work of several contractors to ensure the project is completed efficiently and accurately. The remit also ensures that all building components and fabrications are quality assured before they are brought to site. This detailed and long-term overview allows the company to future-proof the building by design engineering for different types of current and envisaged developments of robots, drones, 3D printing and additive manufacturing, for decades of maintenance to come.

The KAFD Metro Hub’s 200m footprint is located in an increasingly busy urban area. It is at the heart of a citywide transport system comprising six new metro lines, 85 stations and more than 100 miles of track. As a result, future maintenance of, and changes to, the structure that necessitate interruption to rail services, are very undesirable. Since the building’s envelope is wide and low, crane access after completion will prove inconvenient; and because the building is a centrepiece of the city and has been designed for a life of at least 60 years, the issues of automated cleaning, maintaining and updating the building over this period have been central considerations since the project’s outset.

The Metro Hub’s envelope comprises a modular cassette system that uses adjustable steel ‘spider’ fixings to support high performance concrete panels over a waterproof membrane. The system has been engineered to make it suitable for future robot access, movement and operation. This means robots referencing the building’s 3D cloud hosted digital-twin, in conjunction with GPS, can calculate routes and locations on the building façade. While robots will literally do the heavy lifting, replacing and carrying away damaged components, airborne drones can be used for inspection and cleaning. This provides significantly better and safer close up access.

The KAFD Metro Hub has been designed so that inspection, monitoring and precise measurement of normally concealed areas behind panels and within the completed building’s fabric are executed by small flying Lidar and camera equipped drones and robots. High resolution building and system performance data collected this way can be shared with, and coupled to, on-site Construction Labs equipped with 3D printers that fabricate components that perfectly fit the structure. Other projects around the world that the company is engineering are planned to deploy Construction Labs from the earliest stages of construction. In this way, mid 20th century methods and devices of mass-production are being replaced by new automated, very flexible, highly controllable and adaptable sets of tools efficiently operated at a local level.

This way of working reduces imports, generates employment and up-skilling, and cuts the environmental and financial costs of transportation. Also, rather than building a single purpose Design for Manufacture and Assembly factory, which requires years of operation to turn a profit, small flexible manufacturing assets are easy to scale through the building lifecycle. This means that the right equipment is always available to match current needs.

The environmental implications of this change in construction methodology are significant to both the industry and society as waste from constructing and maintaining buildings starts to become a thing of the past. It is estimated by the European Commission that 25-30% of all waste in Europe is generated from construction. The introduction of digital technology makes construction as efficient as any advanced manufacturing process where precise component quantities are made to order. Because these have assured quality and exacting specifications, they are guaranteed to match the structure and have predictable performance over a pre-determined lifecycle. Additional value is produced because, as in a modern mass-customisation car factory, every part is accounted for and there is no waste.

Deploying modular and cassette façade design methodology means buildings can easily be modified to take advantage of new technologies as they arise. In coming years, high performance concrete and steel components will have evolved to become stronger, lighter and more durable. New building materials will also be developed and faster 3D printers working on- or off-site will make optimised components to be fitted by new types of robots. Many building owners and operators will, by these means, simply adapt, refresh and renew buildings throughout their lives to suit contemporary needs.

Building weight is also important, because each extra kilo requires more energy and resources to manufacture, transport and assemble, as well as to heat, cool, clean and maintain after construction. Therefore, precise weight calculations are made for all Newtecnic projects so that true and consequential extended costs can be accurately calculated. It is important to calculate weight when components are being re-purposed or recycled and it means that machines with the capability to handle components can be more precisely optimised when their designers know exactly how much these will have to lift.

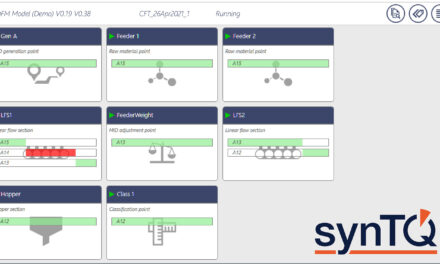

Like a constantly updated digital user-manual, all the information required to construct and operate buildings, and their interconnected machines and systems, can exist within the building’s 3D digital-twin simulation model. This is available on the cloud for investigation, examination and testing at any time from the earliest design stage. Concepts for robots and drones are included together with manufacturing, construction and disassembly instructions and methods.

The merging and blending of these advances indicates that construction is on the cusp of a revolution. Applying first principles, appropriate technology, and thinking of buildings not just as a kit of parts but as systems that can change, develop and adapt over time, means their useful life can be extended while staying relevant for future generations.