Dudley Industries is a company synonymous with high quality sheet metal engineering and partnering with businesses across differing industrial sectors – ranging from construction fit-out to instrumentation manufacture.

Dudley Industries is a company synonymous with high quality sheet metal engineering and partnering with businesses across differing industrial sectors – ranging from construction fit-out to instrumentation manufacture.

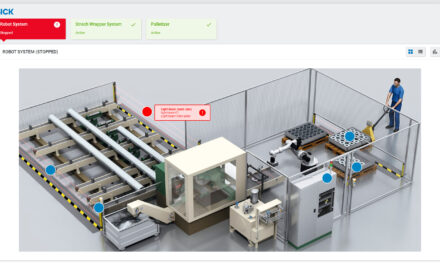

An engineering led company which practices 5S and lean manufacturing techniques, Dudley Industries provides a full manufacturing service encompassing design, development, refinement and manufacture of customers’ standard products and bespoke requirements. Dudley’s aim is to continually improve and exceed customer expectations in terms of performance and cost. This is managed through company practices and procedures that are externally audited and accredited with the requirements of ISO 9001:2015, in addition to applying a ‘right first time’ DFM and DFA philosophy.

At the heart of the business is a highly experienced team of designers and manufacturing engineers led by the design manager, Richard Hooke, who has 32 years of experience in the industry. There is a high degree of crossover between design and manufacturing functions and this multi-disciplinary approach enables the team to take products quickly from concept to full production.

Significant investment has been made in laser cutting and robot finishing equipment. This combines with Dudley’s laser, punch and etching machines which are directly linked to the CAD system, along with CNC controlled folding machines and a variety of presses and rolling machines. This computer controlled design and manufacturing process ensures maximum accuracy and flexibility. It also gives Dudley Industries the ability to vary production from small batches to full scale runs. Commenting on the kind of work the company carries out, Hooke said: “We predominantly work in sheet metals of various materials from 0.5mm to 4mm thickness. We have jobs on the go where the customer has designed the product and we are producing to their drawings.

However, in that scenario we work with the customer to understand what they want and refine the design to improve the product and costs. We also provide a full service from initial concept sketches to full design drawings and manufacture.”

Dudley Industries is currently working with major businesses providing bespoke housings for equipment ranging from high end scientific instrumentation for laboratories to printers used in industrial settings. In the past the company has also manufactured vending machines, CCTV camera housings, security boxes, medical waste boxes, pest control products, to name but a few.

For more information visit Dudley Industries www.dudleyindustries.com

For more information visit Dudley Industries www.dudleyindustries.com