Although electronic enclosures aren’t industry specific, engineers have to be clear on the suitability of an enclosure for their application and sector. From automotive to marine, military and more, Deltron can offer aluminium enclosures to safe house circuitry for numerous markets. However, selecting an enclosure is very dependent upon the environment it will be used in. So which enclosures are best suited to which industries and applications? Below, Deltron Enclosures explains the characteristics of their most popular ranges (General Purpose, Heavy Duty and IP Rated) and what they are used for.

Although electronic enclosures aren’t industry specific, engineers have to be clear on the suitability of an enclosure for their application and sector. From automotive to marine, military and more, Deltron can offer aluminium enclosures to safe house circuitry for numerous markets. However, selecting an enclosure is very dependent upon the environment it will be used in. So which enclosures are best suited to which industries and applications? Below, Deltron Enclosures explains the characteristics of their most popular ranges (General Purpose, Heavy Duty and IP Rated) and what they are used for.

Light Duty Environments

Light Duty Environments

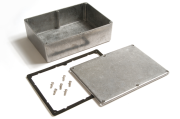

Deltron’s collection of General Purpose enclosures are designed for clean and moisture free environments where ingress protection is not considered a priority. They are manufactured from die cast aluminium, a popular and somewhat traditional material due to its strength and lightweight properties. These are easy to machine and so can be customised with keypads and control systems for industrial applications. Screens can be added to create display boards along with other machining options, or they make excellent housing for raspberry pi devices. As with all Deltron ranges they comprise a variety of sizes and have a standard finish of plain aluminium but a powder and nylon coating are also available on request.

An additional variety in the Deltron portfolio is Plastic ABS enclosures. These are a multi-purpose, low cost alternative, obtainable in a variety of eye-catching colours, including clear. Frequent uses are instrumentation boxes, entry system controls and display screen holders.

Engineering Applications

Heavy Duty enclosures are the most recent additions to Deltron Enclosures and are extremely popular within the electronics market due to their versatility. The robust design appeals to engineers across many industries, including, but not limited to; automotive, transportation, security, lighting and medical. Extra external protection is also provided by the sturdy design, minimising corrosion and impacts from heavy objects. Typical applications for this range include industrial controls, test and measurement equipment, lighting circuitry, security electronics and more.

Waterproof Solutions for Tough Environments

For particularly demanding industries, Deltron manufactures rigorously tested waterproof enclosures up to the highest classification on the internationally known rating system; IP68. An IP66 rating offers full protection from dust and high pressure jet water for up to three minutes, whereas IP68 protects from complete immersion in water of up to five metres for one hour on our standard range of enclosures, and up to 10m for 20 hours on our Heavy Duty range. This high level of ingress protection, together with their EMI and RFI protection capabilities, make the enclosures ideal for use in high humidity, underwater applications and for potential subjection to heavy spray. Such demanding industries include offshore oil and gas companies, marine applications, water treatment facilities, food processing, military and aerospace. However, they are also a popular choice for outdoor applications where they may be exposed to harsh weather conditions, CCTV security equipment and traffic management being just two examples.

What Next?

Once the enclosure has been selected, it may be necessary to have the box machined and painted to meet your particular requirements. Deltron can meet these specifications with the wide range of process and finish options available, including milling and etching, drilling holes, adding inserts, painting and silk screening, adding handles, slots and more. Not only does it make the products ready for immediate use once on site, but it can save significant amounts of time and money through minimum logistical costs and lead times, whether low or high volume production runs.

Why not give us a call and let us help to find the right cost effective solution for your project?

Deltron Enclosures

01724 273206