Here at EMKA we have always believed in the development of our own in-house capability for the engineering and production of our products – a case in point is the wide range of extruded gasket profiles which we produce at our subsidiaries in Spain and here in the UK at our Castle Bromwich plant in Birmingham. At the beginning of the year we announced a doubling of production across the group and now we have taken the step of making a major additional investment in further new tooling for gasket section production covering extrusion, multi-section assembly, multi-material production, incorporation of wire and steel carriers as well as for pre-assembled frames and custom sections.

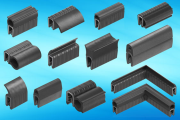

As a specialist hardware company we are pleased to carry extensive stock of standard gasket profiles for enclosures, cabinets, vehicles, HVAC and similar. These extruded sections provide a simple and effective means of sealing to common IP ratings such as IP44, IP55, IP65, IP66 protecting against ingress of dust or liquids when installed face-to-face between a door and cabinet frame. Other sections install edge-to-face and yet others seal inspection windows or provide a wiping action. Paint protection and compensation of varying gap thicknesses are further important uses for gasket sections.

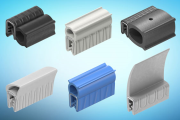

Profiles in EPDM, neoprene, PVC, black nitrate and natural rubber cover traditional expanded closed cell (self-adhesive) foam, through wiping blade and bubble or P type sections, with self-grip (clip-on), channel fixing and window type (with expansion insert), to more complex multi-functional and custom designs perhaps with fillers or flocked weather strips and supported sections with internal or flange structural support.

The range includes EPDM, NBR, CR, PVC and silicone, as well as fire protection and hygiene specifications. Specialist considerations regarding shore hardness, tensile strength, recoil elasticity, abrasion resistance and climatic/chemical resistance can also be advised upon and allowed for in custom production.

In addition to electrical/electronic enclosures and cabinets, many standard sections are available specifically for applications such as motor vehicles, railway carriages, and off-road trucks and machines such as agricultural equipment and fire trucks. Coaches and motor homes also feature with moulded sections to suit doors, windows and ventilation panels, as well as external storage compartments. In addition EMKA offer a bespoke custom design service – where there is a requirement for a really different profile then the team here at EMKA are delighted to design, develop and produce to suit specific needs.

EMKA supplies gaskets of silicone and the synthetic ethylene propylene rubber EPDM. Depending on the requirements and the area of application, the suitable material has to be selected so that the sealing system works in practice. For switch cabinets, EMKA mainly uses EPDM for soft and foamed rubber gaskets. We also offer a combination of soft and foamed rubber as a hybrid solution.

Specialist gaskets for fire protection and hygiene purposes in HVACR and food industries.

Our general purpose 1016 self-adhesive series of gasket sections is available in fire resistant versions to UL94 VO and 94HB ratings as an expanded closed-cell neoprene in stock strips from 3mm to 80mm thick and in standard widths from 10mm up to 80mm, with complete custom capability, e.g. for sheets and punched shapes.

Lip-on P sections for sealing of enclosure and cabinet doors are available in low smoke, low toxicity EPDM, offered to DIN EN 45545-2 suitable for rail industry use and other specialist risk areas. Silicone sections are available for high temperature installations.

HVACR gasket sections.

These profiles are covered by guideline 6022 issued by the VDI association which describes the minimum hygienic standards for ventilation and air conditioning systems. Our 6022 program gaskets enable system builders to meet these requirements for planning, installation, operation and maintenance of ventilation and air conditioning systems in order to guarantee a suitable hygienic condition of the system as well as outside air inlets for air-conditioned premises.

These profiles are covered by guideline 6022 issued by the VDI association which describes the minimum hygienic standards for ventilation and air conditioning systems. Our 6022 program gaskets enable system builders to meet these requirements for planning, installation, operation and maintenance of ventilation and air conditioning systems in order to guarantee a suitable hygienic condition of the system as well as outside air inlets for air-conditioned premises.

In line with the latest engineering and production practices, these profiles are intended to guarantee a high degree of sealing and longevity using either self-clamping edge fitting or U channel mounting within the door where they enable the system to run at overpressure without loss. They contain dust and other pollutants within the filter pathway where they can be effectively removed before air is delivered into the workplace or public areas. In addition they contain anti-bacterial and other additives preventing the spreading of bacteria, spores, fungi, mould and viruses to supplement their normal sealing properties.

Food and Hygiene applications.

Hygiene gasket profiles for the food industry (in silicone) are certified according to FDA or by EHEDG (European Hygienic Engineering & Design Group) and are resistant to sterilising agents, vapour and concentrated cleaning agents, in order to meet the demands of frequent cleaning and sterilising demanded by this high stress application and the level of wear and tear this implies.

EMKA (UK) Ltd

Tel: 024 7661 6505

Email: emka@emka.co.uk