Emerson is your single source for a wide variety of ASCO™ fluid-handling components; including miniature pinch, liquid isolation, proportional and general service valves, as well as fittings, manifolds, tubing and pressure regulators. Not only do our products accommodate unlimited configurations, but they achieve the highest levels of precision, functionality, safety, and efficiency required by clinical diagnostic applications – all while featuring the lowest power consumption in the industry.

Emerson is your single source for a wide variety of ASCO™ fluid-handling components; including miniature pinch, liquid isolation, proportional and general service valves, as well as fittings, manifolds, tubing and pressure regulators. Not only do our products accommodate unlimited configurations, but they achieve the highest levels of precision, functionality, safety, and efficiency required by clinical diagnostic applications – all while featuring the lowest power consumption in the industry.

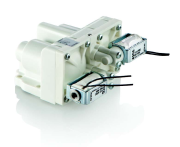

ASCO’s Rapid Engineered Solutions program can deliver ASCO™ customized miniature valve assemblies in a matter of days to analytical and medical instrument original equipment manufacturing (OEM) customers.

“Our Rapid Engineered Solutions program recognizes that OEM design engineers have compressed product development times as they strive to be first to market,” said Andy Duffy, Vice President, Sales – Americas. “Now, analytical and medical instrument manufacturers can get custom miniature valve assemblies in days, not months while simplifying their fluidic paths, maximizing efficiencies, and reducing costs.”

ASCO’s Rapid Engineered Solutions delivers:

ASCO’s Rapid Engineered Solutions delivers:

• In 2 days, valve samples and manifolds from ASCO’s standard catalogue offering.

• In 5 days, engineered valve samples with customizations to meet the application’s needs. Customizations include seal materials, flow and pressure range adjustments, power requirements, electrical connection configurations, and mounting configurations.

• In as little as 10 days, engineered solution tailored to the OEM’s specific application requirements to simplify their fluidic path and turnkey installation. Solutions include engineered valves (pinch, isolation, proportional, and general purpose valves), custom manifolds, fittings, wire harness assembly, filtration, and sensors as needed.

The new program leverages the expertise and resources of the company’s Analytical and Medical team in Europe, the Americas, and Asia. These groups have in-house additive manufacturing capabilities and can rapidly deliver 3D printed assemblies to verify fit and functional prototypes for validation testing.

Once the OEM’s instrument is released to production, ASCO’s engineered solution will be built in one of their three Class 8 equivalent clean rooms to minimize contamination.

Once the OEM’s instrument is released to production, ASCO’s engineered solution will be built in one of their three Class 8 equivalent clean rooms to minimize contamination.

Our Rapid Engineered Solutions are ideal for OEMs designing clinical diagnostic instruments, bioinstrumentation, chromatography, hospital and dental equipment, industrial analyzers, patient monitoring, and surgical and oxygen therapy instrumentation. Their valves’ very low internal volumes minimize fluid cross-contamination and boast excellent flushability. Optional power saving functions are available for improved energy efficiency, plus all customizations are designed for manufacturability.

From concept to production, we’ll deliver your complete solution, including valves, electrical terminations, pins and housings, in as little as 10 days. Find out more on https://www.emerson.com/en-us/automation/brands/asco/rapid-engineered-solutions

From concept to production, we’ll deliver your complete solution, including valves, electrical terminations, pins and housings, in as little as 10 days. Find out more on https://www.emerson.com/en-us/automation/brands/asco/rapid-engineered-solutions