Modern road bridges are typically constructed using mobile cranes to lift prefabricated bridge beams onto support columns. Heavy-duty hydraulic cylinder jacks support the ends of each bridge section to enable accurate height adjustment prior to final positioning. Engineers require rugged sensor systems that detect the position of each cylinder accurately.

These sensors need to be mechanically robust and must withstand harsh outdoors conditions. – Read more here.

The application

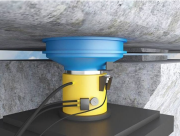

A specialist lifting company uses heavy-duty hydraulic cylinder-jacks to position prefabricated bridge sections during roadway construction. A bridge single section requires up to 20 jacks for accurate positioning, with each jack having a capacity up to 1,000 tons with a stroke up to 30mm (1.25 in). On-site conditions are harsh with cylinders exposed to water, mud and dirt, and may also be subject to mechanical shock and vibration.

The company requires rugged sensors that operate reliably and accurately in the demanding environment. Historically, engineers checked the position of each cylinder manually; this was both time-consuming and subject to human error. Previously trialled sensors were insufficiently robust, necessitating frequent adjustment or replacement, and had inadequate sensing distances.

A simple, contactless system must provide fit-and-forget operation with extended maintenance intervals. The sensors need to be mechanically robust and must withstand prolonged exposure to the harsh outdoor conditions of a construction site. An industry-standard interface is highly desirable to avoid the need for specialised control systems.

The solution

Rugged Extra-Distance inductive sensors from Contrinex’s 500 Series are ideal for this application. Highly reliable and rated to IP67, these units are robust and accurate. A one-piece M30-diameter chrome-plated brass body with PBTP sensing face and vacuum-encapsulated electronics make this device well suited to the hostile environment, and the sensing distance of 22mm allows fully contactless operation.

On each jack, a single sensor is fitted on a metal bracket that is welded to the side of the cylinder; a bearing plate, mounted on the end of the ram, distributes the load onto the bridge section. During operation, the ram extends, lifting the section; when it reaches the desired height, the sensor detects the position of a small metal target mounted on the bearing plate, halting the ram.

The sensor is configured with an industry-standard PNP normally-open interface, and connection to the jack’s hydraulic control system is via an integral M12 connector and PVC-sheathed cable; this allows easy removal and replacement during routine maintenance. The sensor is impervious to water ingress, mud and dirt; reliability has been excellent. Contrinex inductive sensors deliver a cost-effective solution that satisfies the customer’s requirements for a simple, fit-and-forget system.