UK Astronomy Technology Centre (UKATC) and Xograph Healthcare, both UK engineering companies, have been presented with igus vector awards for the challenging and innovative use of cable carrier systems.

UK Astronomy Technology Centre (UKATC) and Xograph Healthcare, both UK engineering companies, have been presented with igus vector awards for the challenging and innovative use of cable carrier systems.

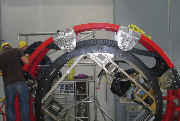

Developed by UKATC, the KMOS (K-band multi-object spectrometer) instrument has been shipped to the Atacama Desert of northern Chile for use in one of the European Southern Observatories Very Large Telescopes (VLT). The four telescopes, when combined, make one of the world’s most advanced optical instruments that allows astronomers to see details of distant galaxies up to 25 times finer than with individual telescopes.

Here, the company has used the heavy duty E4 chain which safely and reliably carries the instrument’s services, including cooling gas pipes and power and signalling cables in the cable rotator (CACOR).

“There are three spectrographs in KMOS, which each employ eight arms that position fold mirrors at user-specified locations,” explains Gordon Taylor, mechanical engineer at UKATC. “The optical and mechanical components of KMOS are also cooled to -140°C in an evacuated cryostat. Therefore there are many control electronics and a closed cycle cooler that requires cooling gas pipes in the instrument. These need to be handled carefully, so there is no risk of twisting or tangling.”

The telescope can be moved through 270° from its initial position in both directions, so another key challenge for the energy chain was its ability to carry the pipes and cables safely through 540° as the instrument turns. The cabling had to be guided individually and igus’ E4 energy chain has a partitioning feature so the different cables and hoses can be isolated and kept separate. The interior separations are easy to use and optimised to be cable friendly. They are made up of only five wear-proof and abrasion-optimised plastic separator bars that can be combined and interchanged. As a result, there is no possibility of the cables becoming tangled.

“We have found the igus E4 chain to be incredibly easy to assemble and user friendly – the links simply click in to place,” said Taylor. “We have tested the chain extensively and are confident that it holds all the cabling and wiring in place, without twisting.”

The second award was for an X-ray machine for the Royal London Hospital that could be transported across bays quickly to help with the fast diagnosis of patients’ conditions. Xograph Healthcare’s team of engineers designed the BuckyStar Resus system, a ceiling-mounted X-ray tube support system that can be moved rapidly from bedside to bedside, without having to move the patient. The position can also be pre-programmed – nurses simply enter the bay number on the control panel and it automatically moves to the desired location.

When designing the system, however, the company was faced with the challenge of how to contain the high voltage and intelligent communications cables as they travelled over large distances.

As a cabling specialist, igus advised on the best approach to take. “We recommended a special low friction rol e-chain because they are lightweight and can travel quickly and smoothly over large distances,” said Justin Leonard, director at igus UK. “The rol e-chains incorporate rollers, which significantly reduce friction and therefore energy loss.”

Nigel Darwell-Stone, business development manager at Xograph Healthcare, said: “Using the low friction e-chain has enabled us to develop an innovative X-ray device which meets the needs of emergency department resuscitation and allows nurses to get on with their day job, rather than being concerned with the operation of the equipment they’re using.”

igus

T: 01604 677240